|

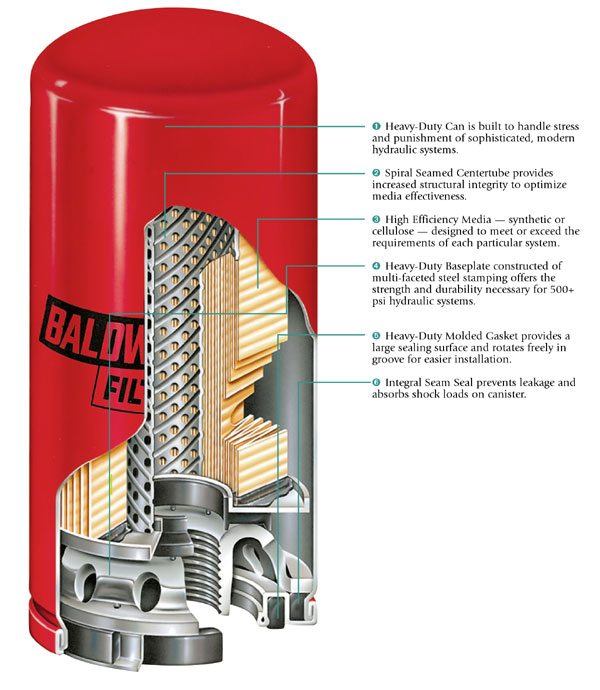

Ask the Expert - Hydraulic Filters Proper Filtration Protects Hydraulic Systems Proper Filtration Protects Hydraulic SystemsAs the sophistication of hydraulic systems and components has increased, so has the importance of system maintenance - especially proper filtration of the system fluid. Today, hydraulic systems run at higher pressures and faster cycle times than ever before. This means closer tolerances in control valves and between all moving parts, greater system stress and increased sensitivity to contamination. Hydraulic system efficiency and reliability depend on good filtration. Perhaps the easiest and most cost effective way to lower maintenance expense and help to ensure trouble-free system operation is through proper filtration. Maintaining systems cleanliness to OE designed requirements is the first step to insure equipment reliability and efficiency of operation. Baldwin Filters Helps Improve System Cleanliness Improving system oil cleanliness levels, providing better cold start performance and meeting service interval expectations are primary objectives in the design of Baldwin hydraulic filters. To accomplish these goals, Baldwin Filters utilizes two types of depth filtration media:

Synthetic Media - The number of applications using synthetic media has grown rapidly since the late 1970s. Synthetic media is the choice in higher pressure, heavy-duty mobile and industrial hydraulic and transmission applications. These man-made glass fibers are very uniform in size and shape. Their aerodynamic characteristics present the least possible resistance to flow, while creating many more uniformly sized dire interception areas. Synthetic media elements may cost slightly more, but offer significant performance advantages, these advantages include lower restriction (especially during cold start situations), improved efficiency to protect sensitive controls and extended equipment life.  Hydraulic Filters From Baldwin Help Keep Your System Going

Hydraulic Filters From Baldwin Help Keep Your System Going Good hydraulic filtration starts with selecting the right filter for each job. The manufacturer's recommendations and the specific applications should be the most important factors in choosing a filter. Expensive hydraulic equipment may require synthetic media to accommodate high flow rates, while maintaining high efficiencies. In cold temperatures, synthetic media often provide better cold start because there is less restriction to the fluid flow. Some systems benefit from the filtration efficiency and contaminant capacity that a cellulose media can provide over the change interval. Equipment owners need to choose their filters based on equipment manufacturer's recommendations, typical working environments and specific equipment demands. Baldwin Filters broad, heavy-duty coverage includes high-strength, hydraulic spin-on filters designed to handle the pressure from today's heavy-duty hydraulic applications. |

| Terms of Use Privacy Policy | Copyright, 2006-2024, All Rights Reserved, Icon International, Inc. |