|

Ask the Expert - Lube Filters Protecting Today's Engines  As modern, high-performance engines have continued to evolve over the past 50 years, so has the requirement for more sophisticated oil filters. While filters play a passive role in engine protection, they nevertheless must work together with the lubricating oil to keep engines protected and clean. As modern, high-performance engines have continued to evolve over the past 50 years, so has the requirement for more sophisticated oil filters. While filters play a passive role in engine protection, they nevertheless must work together with the lubricating oil to keep engines protected and clean.

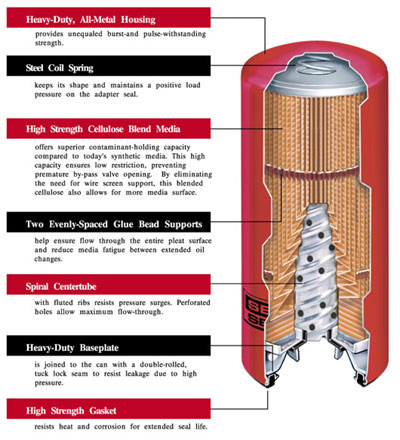

Modern oils play vital functions in protecting engines, especially in heavy-duty situations such as trucking, construction, mining and agriculture. Lubricating oil acts to reduce friction and wear, cool engine parts, seal combustion chambers, clean engine components and inhibit corrosion. These functions are carried out by special additives in the oil, which complement the action of the oil itself. The protective action of the lubricating oil and its additives are supported and balanced by the work of the lube filter. Lube filters, particularly those designed for heavy-duty applications, have the sole purpose of keeping damaging contaminants away from sensitive engine parts. Filters trap oil contaminants in two ways: Some particles adhere to filter media as the oil flows through the filter. Such particles attach themselves to the media surface without plugging up the media pores. Other particles are trapped in the filter media by the pressure of the oil as it flows through the filter. As the oil changes direction in its path through the filter, particles are driven or impinged into the media. Ideally, most of these particles are trapped in the outer portion of the media, leaving inner media surfaces open to continue catching particles that slip through. Eventually, however, media pores will fill up and the filter begins to lose its effectiveness. A Close-up Look at Filter Media As engine power has increased, so have bearing loads, engine rpms and operating temperatures. With the introduction of combination full-flow/by-pass filters, equipment operators have gained added efficiency in their vehicles performance. However, as newer engines have been designed with improved oil control, oil drain intervals have been increased to account for lower oil usage levels. This means that lube filters must be more effective in trapping oil contaminants, and oil drain intervals must be monitored more closely to prevent excessive engine wear. For example, as oil sump capacity decreases, the concentration of fine contaminants in the sump increases. This requires both the oil and the filter to work more effectively to keep particles out of the engine. Filter media today ranges from the long popular and proven cellulose to synthetic media made of fiberglass, polyester, microglass and various blends of these materials. Each type of media has specific applications for which it is best suited. Cellulose filters are high in efficiency and capacity, yet low in cost. Typically, cellulose filters are rated 98% efficiency at 40 microns. Cellulose media is used in varied oil, air, fuel and some hydraulic applications. Microglass filters generally have high efficiency, and media pore size can be controlled to catch small particles. This is especially beneficial for hydraulic oil filtration where 3 to 5 micron filtration is desirable, and hydraulic oil is not warmed by engine heat. The drawback to glass media filters is that the media cannot be bent too sharply in forming the filter pleats or the glass fibers will be broken. This limits the surface area that can be built into a glass media filter. Also, glass media typically requires a wire screen lining to keep the glass fibers together. Newer filters for heavy-duty use are now being made with a combination of cellulose and synthetic media. This blend of fibers provides improved efficiency, along with increased dirt-holding capacity. Although cost for these filters is greater than regular cellulose filters, the cost can be lower than for microglass. These filters are ideally suited for severe service and extended service intervals. Filter Construction Is Critical to Performance  No matter how efficient the media, lube filters must stand up to tough operating conditions for hundreds of hours or thousands of miles. Over the years, Baldwin has designed and built special machines to perfect filter construction. Innovations include: State-of-the-art high-speed equipment to give filter pleats exceptional uniformity for maximum efficiency in oil flow and contaminant collection. No matter how efficient the media, lube filters must stand up to tough operating conditions for hundreds of hours or thousands of miles. Over the years, Baldwin has designed and built special machines to perfect filter construction. Innovations include: State-of-the-art high-speed equipment to give filter pleats exceptional uniformity for maximum efficiency in oil flow and contaminant collection.

Centertube forming equipment to form a spiral seam that is actually stronger than the material itself. This lets the centertube better withstand sudden changes between internal and external pressure. Special can/baseplate seaming techniques with double-rolled lock seams to withstand pressure and vibration. Heavy-duty baseplates which are cold-formed to create a solid platform that doesn�t bend or twist under high pressure surges. Does Extended Oil Change Interval Pay? Baldwin engineers have been researching extended oil drain intervals in the field for more than 30 years, as have most engine and equipment manufacturers. These engineers agree that extended drain intervals should be approached with extreme caution. While extended intervals may save a few dollars in the short run, improperly managed intervals can lead to accelerated engine wear and costly engine rebuilds. When considering extended drain intervals, it's important to develop a consistent oil analysis program. Another factor to consider is that oil consumption tends to increase toward the end of extended change intervals, because engines burn more used oil than new oil. Increased oil usage reduces the savings from extending the drain interval. When evaluating the value of extended change intervals, a key factor for selecting lube filters is capacity - the amount of contaminants the filter can hold before it begins to plug. As oil begins to deteriorate, soot and sludge accumulate in the filter and can rapidly plug the filter media. Lube filters with higher capacity protect the engine better when oil change intervals are extended. Whether your equipment can tolerate extended oil drain intervals depends on such variables as operating environment, engine types, oil used, etc. Consider miles traveled vs. hours of operation. Linehaul trucks averaging 80,000 miles per year may handle extended drain intervals better than local service trucks that travel less than 40,000 miles per year, for example. Remember, too, that the accumulation of oil contaminants builds up over time, regardless of miles traveled or hours operated. Extended oil change intervals don't lessen the need for effective preventive maintenance, including regular oil analysis. In fact, it amplifies it! Baldwin Severe Service Filters Outperform Synthetic Media Filters Responding to today's demands for effective lube filtration for high performance engines, with the capacity for extending oil change intervals, Baldwin Filters has introduced a new line of "Severe Service" filters. Severe Service filters incorporate the proven effectiveness of cellulose media, blended with synthetic media technology. Under appropriate conditions, these new filters have extra efficiency and capacity to handle extended drain intervals. On the other hand, for equipment operating under extreme conditions, Severe Service lube filters provide added protection against harmful oil contaminants. |

| Terms of Use Privacy Policy | Copyright, 2006-2024, All Rights Reserved, Icon International, Inc. |